Recycling Plastic Cutlery into 3D Printing Filament

I’m pretty regularly in the US, and I love being there, but one of the worst things I have always have to experience, at least from the view of a European, is the amount of waste that’s generated every day. One of the things I find particularly bad is the use of single-use cutlery. I mean, it makes complete sense for takeaway food, but I don’t understand why it’s also used in hotels or even large corporate canteens! Yes, you don’t have to wash it for re-use, but other than that, it’s just horrible! It doesn’t cut properly, it’s flimsy, it’s weak, and even gets soft when hot. Yet, I’ve seen more and more knives, spoons, and forks being labeled as compostable, so theoretically, these can go into the food waste bin if your local facilities accept them. This type of plastic utensils are usually made from PLA or Polylactic acid, which is a bio-plastic that, under ideal conditions in an industrial composting plant, will biodegrade. But PLA is also the most popular material in 3D printing, so I thought, could we recycle compostable plastic cutlery into new 3D printing filament?

Compostable Cutlery

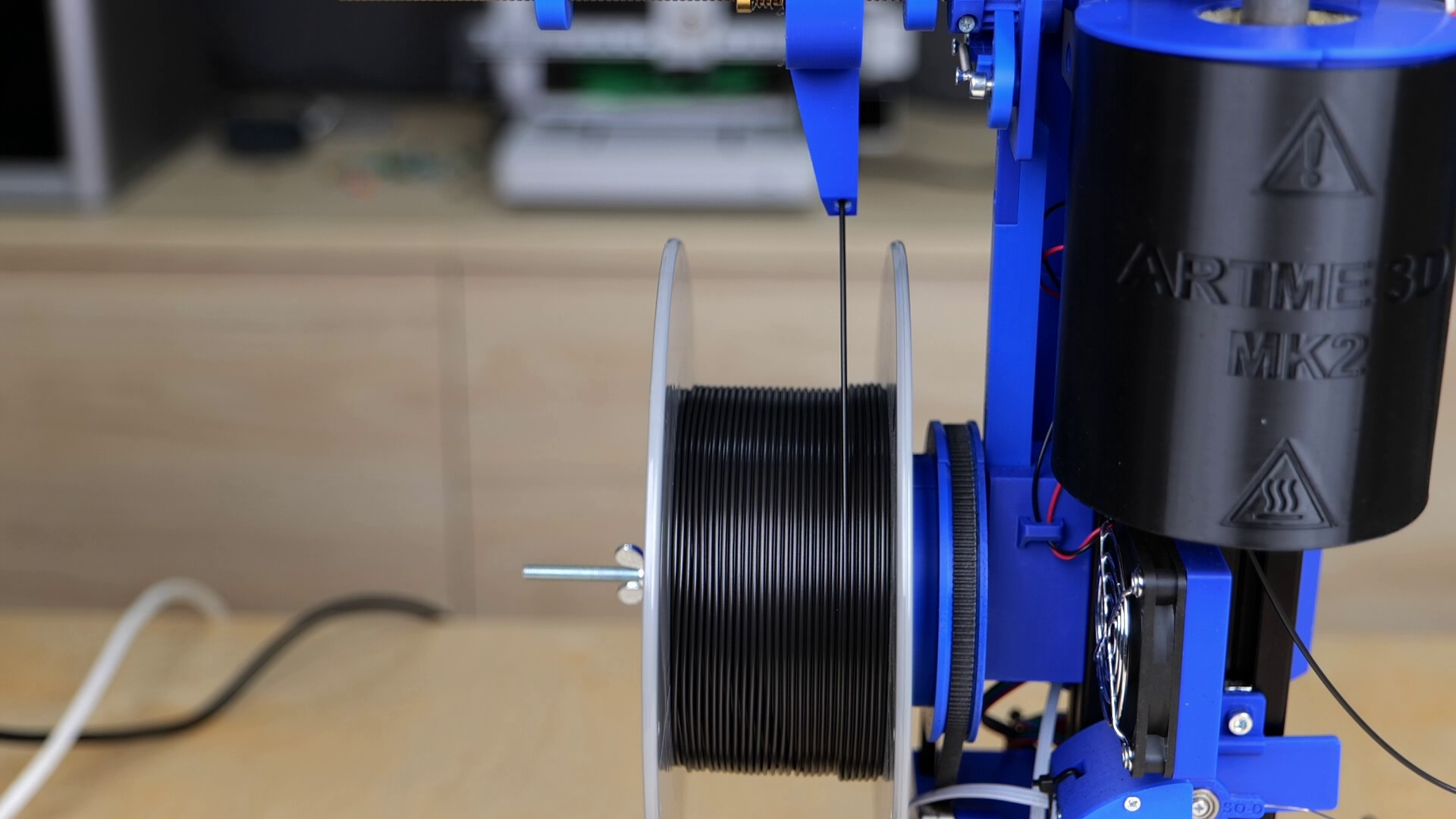

So I went to one of our dollar stores, or rather, one Euro stores, and got a couple of packets of compostable cutlery. Both said PLA on the packaging, so this should be a good start for the test. The not-so-great start was that these utensils felt really brittle, and I don’t really want to know how you could eat with them. But let’s see if that also translates into the filament. I’ll be using my new desktop filament extruder to recycle this material. The Artme3D will feed the plastic into a long meltzone using a screw and then extrude a thin filament that gets wound onto a spool. Yet, our forks and knives obviously won’t be able to fit the extruder and will need to be shredded. I used a blender for this in the past, but this was less than optimal, so I opted for a proper plastic shredder that 3DEVO provided a while back.

Artme3D Filament Extruder

I first started out by cleaning my shredder from the leftovers of my last projects. Once I had most of the old material removed, I turned it on to process our compostable cutlery. I first broke them in half since the whole forks and knives were too big to fit the feeder. Due to the brittle nature of the plastic, they shredded very easily and within a couple of minutes, I had a full tray of small plastic pieces that once were throw-away plastic. If we want to extrude filament, the plastic must be dry, so I put all the shreddings onto a tray and put it into my drying oven for some hours.

Shredding the Cutlery

After all of the remaining moisture had evaporated, I was ready to start the first extrusion test. I turned on the Artme3D and pre-heated it to 175 °C. I poured in the shredded material and started the extrusion process. The first material that came out of the nozzle was the leftover from the last experiment.

Adding the shredded material to the hopper

At some point, the extruded filament turned from clear to black, indicating that we transitioned to our shredded material. I guided the filament through the position sensor to the puller, which pushes the material to the filament spool. Even though I already lowered the extrusion temperature I directly noticed that the strand of material was significantly thinner than the 1.75 mm target diameter we need for 3D printing. The reason is probably that the PLA used for the cutlery is meant for injection molding. These types are thinner in consistency when molten, to easily flow into the molds. Since we rather need a gooey consistency, we can combat that by decreasing the temperature.

Material Transition

So I lowered the temperature to only 170 °C but I didn’t get over 1.5 mm in diameter. This was still a bit away from ideal, but if it’s consistent, we can correct for a thinner filament during printing by increasing the flow rate. So I started the spooling process. Usually, you simply feed the end of the filament through a small hole on the side of the spool and bend it over to fix it in place. Yet, similar to the utensils we started with, also the filament was really brittle and just snapped off, when I tried to to bend it over. So instead of bending it, I simply used a bit of tape to fix it to the spool, which allowed me to start the winding process.

Fixing the brittle filament to the spool

Since the filament diameter was still around 1.5 to 1.6 mm I decided to further decrease the temperature to only 165 °C. This worked okay for a bit until, I think, the temperature dropped even lower than the set value, and the molten plastic got so thick that it didn’t extrude consistently anymore, and I was able to see pieces of unmolten material on the strand. Once this deformed material reached the reel, it cracked and part of the already spooled material unwound. So, I slightly increased the temperature again, removed the failed attempt, and reattached a new end of the filament to the spool. Then I just left everything as it was and tried to wind as much filament as possible, made from 100% plastic cutlery! This time the spooling process went well for quite a while until, at some point again, the filament jumped a bit and broke again. I took this as an opportunity to call it a day for the current batch, flushed out the leftovers with fresh PLA pellets and inspected the result.

Untangles Filament Spool

The material was really brittle, yet it seemed to be usable. So I loaded it into my Prusa Mk4 and printed the first 3D Benchy with it. To compensate for the smaller diameter, I increased the flow rate to 130% in the slicer. I didn’t notice any major problems during printing besides a bit of stringyness. The surfaces didn’t look super smooth, but the matte appearance of the material gave the boat a neat look. On closer inspection, I was able to see some flaws on the outer walls and a bit of under extrusion, but hey, first try and this used to be old plastic forks and spoons. The print of my Mini Me, unfortunately, showed one of the major flaws of the material, and this was the really bad strength because I simply ripped the feet off the model when removing it from the buildplate.

3DBenchy

Yet there might be a solution to this. Even conventional injection molding often uses shredded and recycled material, yet barely anyone uses 100% of old material. In order to ensure good properties and process stability, they usually add a small amount of new, virgin pellets to the shredded mix. Since our material made from black plastic cutlery was almost as brittle as glass, I did a second batch with the leftover material I had but made a 50/50 mix of shredded material and PLA pellets and put that into the hopper.

The mix fed and extruded really well, and I was able to achieve an average diameter of 1.6 to 1.7 mm. The filament spooled very well, and I didn’t have to use the tape trick to hold the material on the spool because the new pellets got rid of all of the brittleness. Once the hopper was empty, I stopped the extruder and removed a remarkably looking roll of filament from the machine. I still compensated the slightly lower filament diameter, but the print results looked really good, still with a nice matte finish.

Perfect winding

There were still two important questions left to answer. Can we get good material from old cutlery with fewer virgin pellets added, and I think the biggest of them all: how does all of the grease, dirt, and grime affect the recycling process when plastic cutlery was used for eating something? Since the white cutlery from the dollar, uh, euro store was just as brittle as the black one, I ordered some name-brand compostable forks and knives from Amazon.

Compostable Cutlery Set from Amazon

These had a similar appearance but felt way less brittle when bent. So I vacuumed out the shredder and fed the new set of utensils. Since it’s really hard to remove even the last bit of old material from the granulator, I ended up with nice white re-grinds yet with some specs of black material and here and there, even a bit of some old colored material I processed in the machine.

Slightly Impure Shreddings

As a first test I thought I’d extrude again 100% recycled material just to see if it’s any better than the black stuff. My first impression of the material was way better than from my first batch and the filament was by far not as brittle as the one from the black cutlery. I still wasn’t able to achieve the 1.75 mm of filament diameter, but even at 168 °C extruder temperature, the average diameter was around 1.6 mm which should be well usable for printing. The ARTME3D is a very compact desk extruder that doesn’t mix the material a lot during the melting process. This resulted in very distinct sections of differently colored material on the spool, where a black particle colored a short section of filament. This resulted in a not perfectly white, recycled roll of material, but I, in a way, really liked the look of it, giving the material a unique, slightly dirty recycled appearance. The material itself printed really nicely with standard PLA setting and only a bit of higher flow due to the lower diameter. The material contamination lead to some really interesting streaks on the prints that I honestly don’t mind at all. The surfaces were smooth, with a matte finish, and even though we worked with 100% recycled material, I couldn’t spot a lot of diameter variation on the parts.

3D Print showing streaks of impurities

“But Stefan”, you may ask, “isn’t using clean forks and spoons right from the package totally unrealistic when you’re saying that this could be a way to recycle post-consumer plastic?” And you’re totally right. And this is why I went into the real CNC Kitchen, and cooked a nice marinara sauce with tomato, onions, a bit of olive oil for the greasiness, and of course, salt, thyme, rosemary, and a pinch of sugar for seasoning. Once this simmered for a bit, I poured it over a bunch of the plastic cutlery I got from Amazon, made sure that all the sides were covered and let it sit for a night.

Cutlery with Marinara Sauce

The next day I washed the cutlery by hand in our sink, so that no big chunks of tomato were still on the utensils and then let everything dry. Back in the studio, I threw everything into the shredder and then dried the regrinds in the oven. If anyone wonders - the material still had a light smell of the herbs I used for the marinara, but nothing really dominant. I wanted to make the last batch perfect. Since our initial test with the white material showed that it was less brittle and significantly easier to get to the right diameter, I only added a small portion of fresh pellets. I weighed 200g of shredded material and added 40g, so 20% of virgin PLA pellets. In order to make the material look even nicer, I also wanted to add a bit of color. I weighed in 2% red masterbatch, which dasFilament very kindly provided years ago.

Shredded material with 20% fresh PLA pellets and 2% Masterbatch

When mixing everything up, it didn’t look like a lot but that masterbatch is very highly concentrated pigments and should be enough for some good coloring. I heated up the extruder for the last time, poured in my mixture of regrinds, fresh pellets, and masterbatch, and started the extrusion process. It took a bit until the old material was purged out, and initially, the filament was only white. Yet, shortly after, I was able to spot that it slowly transitioned to a nice, pastel red color. I guided the filament to the puller, and after checking that the diameter was consistent, I started the spooling process. And oh boy, did that filament look beautiful. I still didn’t get to the 1.75 mm filament width, but the diameter was consistent, and the surface looked gorgeous. I wore a respirator most of the time, yet even in between, I, unfortunately, wasn’t able to notice a smell of freshly cooked pasta, so I either cleaned the cutlery well enough or the remains were just not enough to overtone the smell of molten plastic. Due to the relatively low amount of mixing, the filament got quite a significant color gradient with different shades of red.

Recycled Filament with red pigments

I didn’t notice any problems extruding this material which bathed in the marinara for a night. The virgin pellets might help, but I think if you make sure that everything is the same type of plastic and properly clean and dry, there aren’t that many things happening with the plastic. And to give you an idea of how good this recycled filament, made from old cutlery prints, just look at this 3DBenchy and the Mini Stefan that I printed. The surfaces are super clean with a very matte appearance, just like the forks and knives initially had. There are no real artifacts due to the smaller and slightly inconsistent filament diameter, and the red gradient on the material is just super gorgeous! Or what do you think?

3D Print with the final recycled batch

This experiment and prove of concept shows, once again, that plastic recycling is possible, if you make sure to properly sort and clean the material. Adding some virgin material definitely helped to reduce the brittleness of the material and reduce thermal degradation. And also the Artme3D impressed me once again. Even though I had a hard time getting the filament diameter right, it was able to produce a well-usable material. It doesn’t mix the melted plastic a lot, but this also results in these really nice color gradients on the material.